The Company

Our Company is young but rich in expertise. Fully aware of the artisan skill that has developed for years in this field, we are able to meet even the slightest customer’s expectation, thanks to our high quality standards obtained through our competent technicians who properly worked for years in the most important companies of this field and have now decided to offer a new opportunity to their customers.

Technical Office

Our staff is specialized and with great experience in the sector. Professional skill is combined with advanced planning technologies and a dynamic and elastic structure, so that, day by day, we can easily change our plans in order to answer to particular delivery requests.

Structure

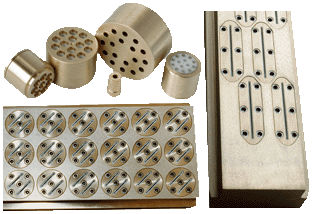

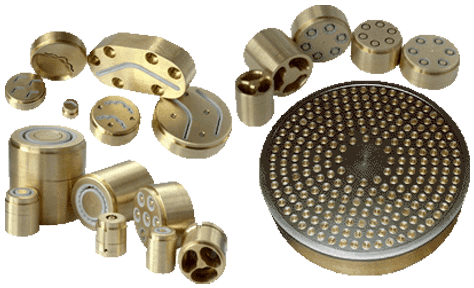

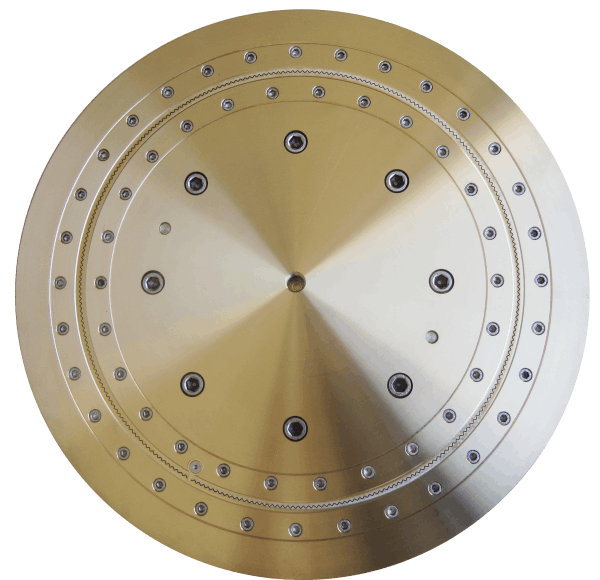

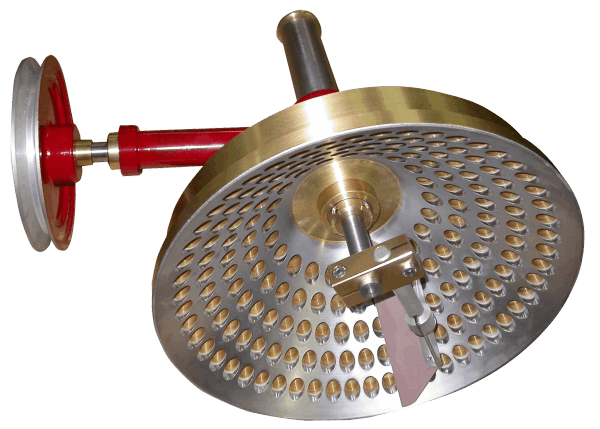

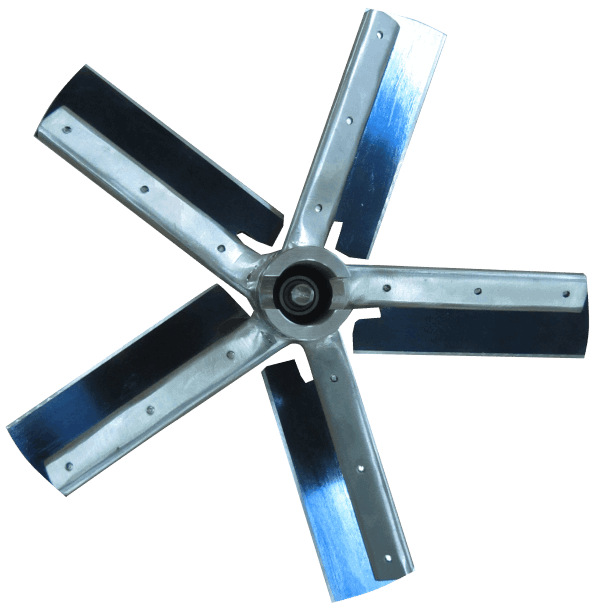

In virtue of this small and elastic structure, we can meet our customers’ needs in a very short time with quotations, technical drawings, plans, etc. We are able to personalize every type of dies, pre-dies, penne cutting disks, dies washing machines and cutting devices, on the basis of pasta producers’ requests.

Commercial Office

Our Sales Department is endowed with both commercial and technical skills.It is able to understand the customer's requests, with whom a collaborative relationship is established immediately.